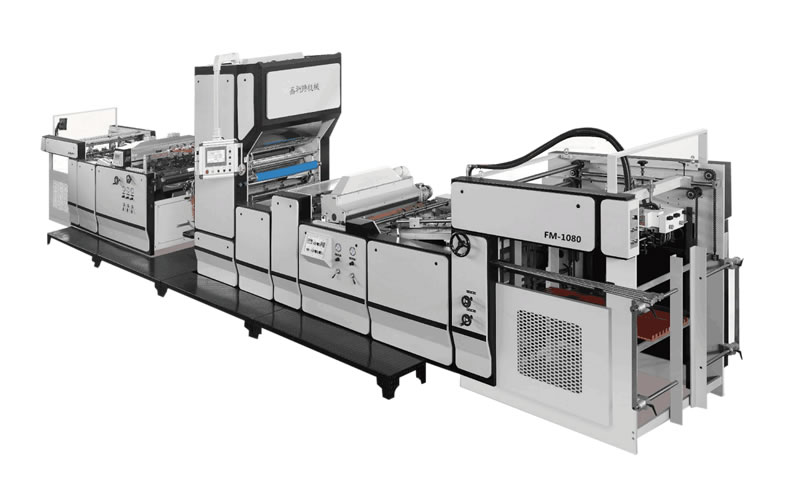

High Speed UV Spot and Overall Coating machine researched and developed adopts upper-swaygripper-pass-sheet method to enable max speed up 9000 sheets/hour. UV curing system with Teflon conveying belt has characteristic of higher speed,precise orientation and UV curing higher efficiency and lower power consumption. After sheet travelling through UV curing higher efficiency and lower power consumption. After sheet travelling through UV coater and being transferred directly by teflon belt, grippers can not be heated by high temperature from UV light, which prevent them from being damaged or deformed to ensure easy maintenance.

① AUTOMATIC PAPER FEEDING PART

High speed feeder with four sucking and four forwarding suckers can feed sheet smoothly

② SHEET TRANSFERRING UNIT

Upper swing sheet transferring method cantransfer sheet smoothly at high speed to pressure cylinder exactly .

③ VARNISH SUPPLY

Steel roller and rubber roller with metering roller reversing and doctor blade design control varnish consumption

and volume to meet the demand of products and operate easily.(Varnish consumption and volume are

determined by LPI of ceramic anilox roller)

④ TRANSFERRING UNIT

After sheet is transferred from pressure cylinder to gripper , air volume blowing for paper can support and reverse

sheet smoothly , which can prevent sheet surface from being scratched

⑤ CONVEYING UNIT

Upper and lower conveying belt can form thin sheet to be curved for smoothly delivery.

⑥ SHEET DELIVERYAutomatic pneumatic patting sheet controlled by photoelectric detecting sensor make sheet pile fall automatically

and collect sheet neatly Electronic control can take out sheet sample safely and quickly for inspecting