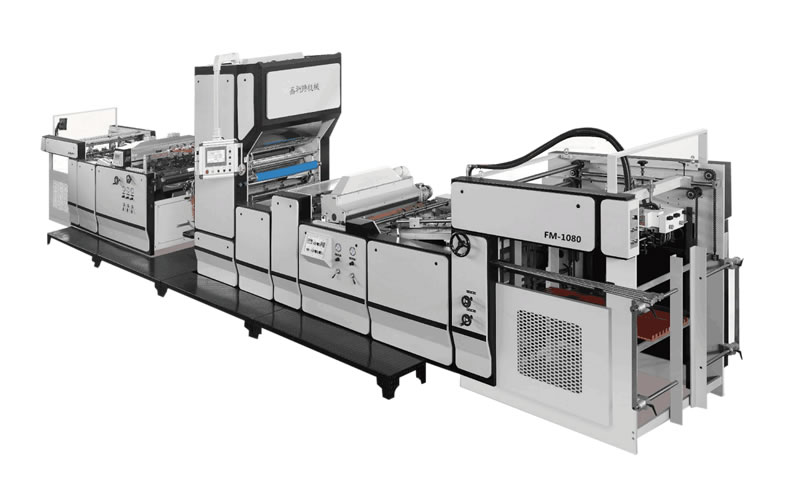

SG-E series UV oil coating machine which is suitable for the varnishing and polishing process of various paper (80-600g/m²), machine for water-based oil, UV oil and blister varnish oil coating, after processing the print surface has the damp-proof and water-proof effects. Machine adopts the reversing mechanism to make the oil layer smooth and fine, save varnish oil and meets the high quality requirements.

SE model adopts air knife system which controlled by memory type PLC. It has the characteristics of beautiful appearance, stable and reliable performance, simple and convenient operation and high automation degree.

FEEDING UNIT

1.High-speed paper feeder, upper and lower limit protection of paper feeding table

2.double-sheet or multi-sheet paper feeding detection device make machine stop, stepless frequency feed;

3.Paper layer table upper protection device, The top side of paper table and feeder with micro-switch to prevent paper from rising too high impact feeder.

SE COATER WITH AIR KNIFE

1.Three-roll reversal speed regulator head ensures water-base polishing effect and no stripe printing

2.Measuring roll is driven by a separate motor to ensure even glue loading.(oil coating roller dia. 185mm)

3.Improved air knife technology for thin paper (80-500g) to ensure that the paper does not attach to the roller after coating and runs smoothly.

4.Add pedal for workers to step on and use, more convenient to debug the machine, and add railing behind the pedal for more safety.

5.Upgrade the touch screen operation center console, more convenient and accurate operation.

INFRARED DRYING AND ULTRAVIOLET DRYING

1.Infrared dryer unit: constant temperature IR infrared lamp unit can set the temperature according to the product requirements.Energy saving, fast drying of water varnish oil, high temperature Teflon belt with automatic deviation correction protection.

2.Ultraviolet dryer unit: 3 pcs of 8 kw UV tube, could choose open 1 group, 2 groups or 3 groups tube, fans cooling.

3.Fan cooling device

NON-STOP COLLECTOR

1.Adopt pneumatic paper sorting structure to ensure the neatness of the paper and facilitate the next process

2.Counting electric eye, the number of running paper is displayed on the display screen at the take-up machine, which can be cleared and accumulated

3.Induction electric eye, sensing the length of the paper, if the length of the paper changes, the belt will accelerate, and the baffle of the take-up machine will overturn and lift the paper