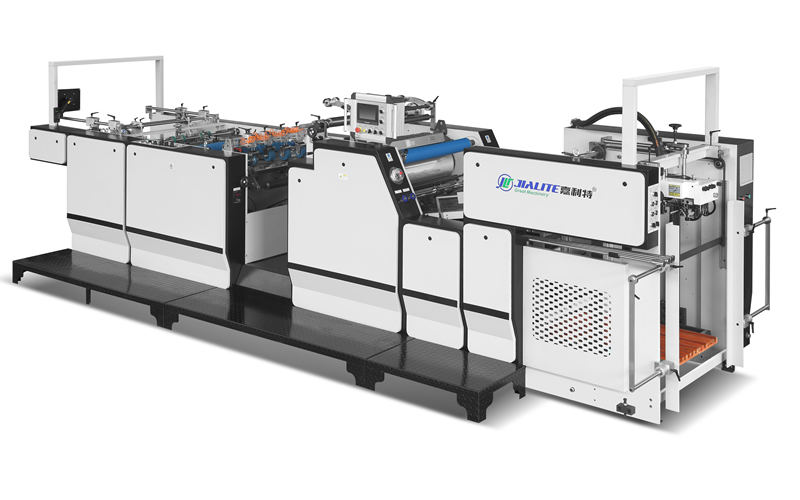

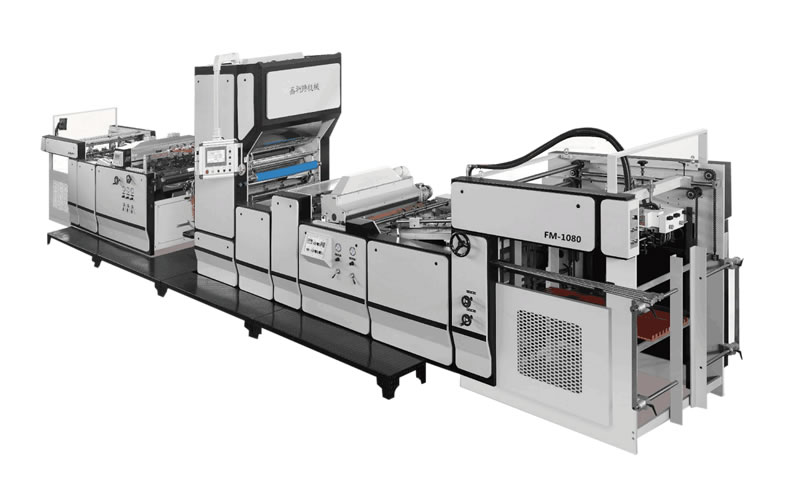

Machine function and Structure

SGZ-II-1200E UV oil coating machine which is suitable for the varnishing and polishing process of various

paper, machine for water-based oil, UV oil and blister varnish oil coating, after processing the print surface

has the damp-proof and water-proof effects. Machine adopts the reversing mechanism to make the oil layer

smooth and fine, save varnish oil and meets the high quality requirements.

Water-based oil, UV oil, Blister oil and Soft touch oil coating

① High Speed Feeder

② First Coater with Air Knife

Three-roll

reversal speed regulator head ensures water-base polishing effect and no stripe

printing.

Measuring roll is driven by a separate motor to ensure even glue

loading.

③ IR Dryer+FAN

④ Second Coater With Air Knife

Three-roll

reversal speed regulator head ensures water-base polishing effect and no stripe

printing.

Measuring roll is driven by a separate motor to ensure even glue

loading.

⑤ UV DRYER + FAN

⑥ Automatic Collector

Automatic

paper receiving, paper collecting and paper organizing function to improve the

operating

satisfaction degree.

|

Model

|

SGZ-II-1200 UV

Oil Varnishing Machine (Double Units)

|

|

Length of Roller

|

1250mm

|

|

Max paper size

|

1150*900mm

|

|

Min paper size

|

390*320mm

|

|

Suitable Paper

Thickness

|

100-600g/m2 (the first coater use water or water base oil coating, the second

coator use UV oil coating)

|

|

Working speed

|

80m/min

|

|

Power

|

380V 3P 50HZ

|

|

Total motor

power

|

80Kw

|

|

Infrared Heating

power

|

22kw (the first

channel)

|

|

Ultraviolet

heating power

|

3×8kw (the first

channel)

|

|

Weight

|

7500kg

|

|

Overall

Dimensions

|

17000×2000×1700mm

(IR dryer 5 meter, UV dryer 5 meter)

|

|

Container

|

1 container of

40 foot container, 1 container of 20 foot container

|

lHigh-speed paper feeder, upper

and lower limit protection of paper feeding table; double-sheet or multi-sheet

paper feeding detection device make machine stop, stepless frequency feed; Paper

layer table upper protection device; The top side of paper table and feeder with

micro-switch to prevent paper from rising too high impact feeder.

lThe first coater with air knife

use for water coating and water base oil coating. (water coater)

lInfrared dryer unit: constant

temperature IR infrared lamp unit can set the temperature according to the

product requirements. Energy saving, fast drying of water varnish oil, high

temperature Teflon belt with automatic deviation correction protection. Fans

cooling.

lThe second coater use for UV

oil coating with air knife, suitable for thin paper UV coating. (UV OIL coater)

lUltraviolet dryer unit:3 pcs of

8 kw UV tube, could choose open 1 group, 2 groups or 3 groups tube, fans

cooling.

lPaper stacker: delivery in good order, the auxiliary paper delivery

table and the automatic paper delivery stacker can be converted and used.

Welcome to our website. If you have any requests or suggestions,please feel free to email us at

[email protected] or use the following enquiry form. Please allow us to provide you with the best service.