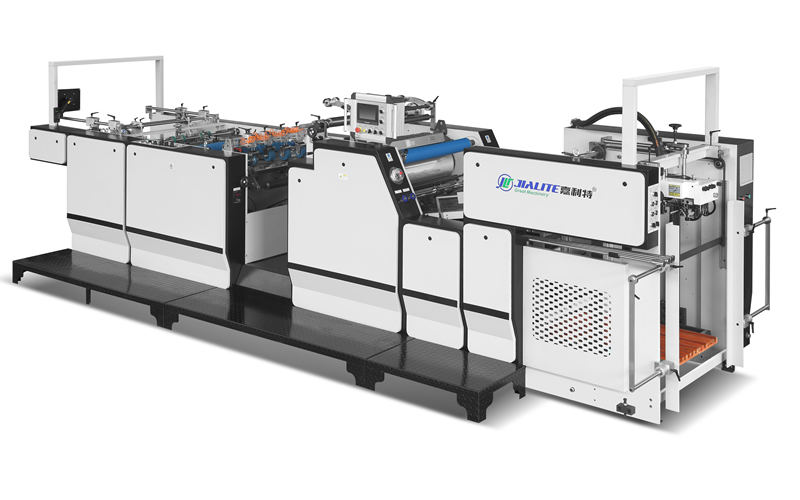

Machine Function and Structure

FM-H fully Automatic Vertical High-precision and multi-duty laminator as a professional equipment used for

plastic film laminating on the surface of paper printed matter.Water-based gluing (waterborne polyurethane

adhesive) dry laminating. (water-based glue, oil-based glue, non-glue film)

Thermal laminating (Pre-coated /thermal film)

Window paper laminating (water base glue or oil glue)

Film: OPP, PET, PVC, METALIC, NYLON, etc.

Application Range

Widely applicable for laminating in packaging, paper box, books, magazines, calendars, carton, handbags,

Gift box, Wine packaging paper improving the printing matter grades, and achieve the purpose of dust-proof,

water-proof, oil proof. It’s the best choice for printing and laminating enterprises of all scales.

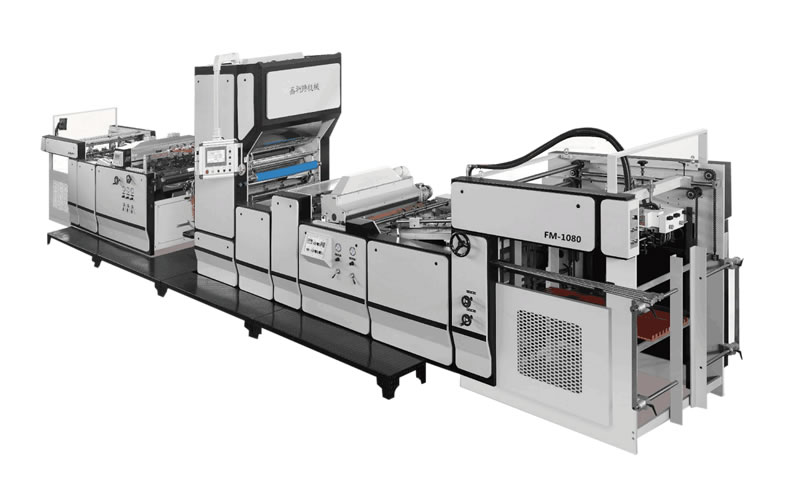

①High Speed Non-Stop Feeder (Servo control)

4 suckers for lifting paper and 4 suckers for conveying paper to ensure stable and fast paper feeding.

Max. feeding speed 12,000 sheets/h.

② Window Laminating Function Details

Paper gluing and IR drying, then laminating with film, special use for food box, Underwear packaging box,

Cosmetics packaging box, Toy box and different kinds of color paper box making.

③ Laminating Unit

H model with large Dia. 1000mm of the dry roller for fast dryer, auxiliary oven could completely open

(front and back).

Double Electromagnetic heating system control

Side opening of auxiliary drying system

Gluing system with Teflon treatment (cleaning easy)

Glue coating and glue measuring roller with thickness Chromium plating treatment, uniform rapid gluing.

Cutting film device: Extra length film precision cutting and recover roll.

Short feeding, machine will stop, this function effectively avoid roll dirty by glue.

Machine operate through removable touch screen, simple operation by one operator.

④ Hot Knife Cutter Unit (include round knife and hot knife)

Cutting mechanism 1:Rotary Fly-Cutter Cutting Mechanism.

Rotary knife cutting can be applied to more than 100 grams paper, production of 100 grams paper need to

appropriate reduce speed. Make sure paper flat after cutting. The fly off knife with 4 blades, bidirectional

rotation, speed synchronization with main machine, also can adjust the speed ratio. With the guide wheel

structure, solve the problem of film edge.

Cutting mechanism 2: Hot Knife Mechanism.

Rotation knife holder.

Heating knife edge directly, working with safe low voltage 24v, Rapid heating and cooling.

Sensor, sensitive detection of paper thickness changes, accurate determine the position of paper cutting.

Display.Hot knife automatically generate different temperature, according to different paper sizes and

dimensions, in order to ensure smooth cutting.

⑤ Non-stop Collector Unit

The automatic paper collecting machine of the laminating machine has the function of collecting paper

without shutdown; the collecting size is matched with the paper feeder.