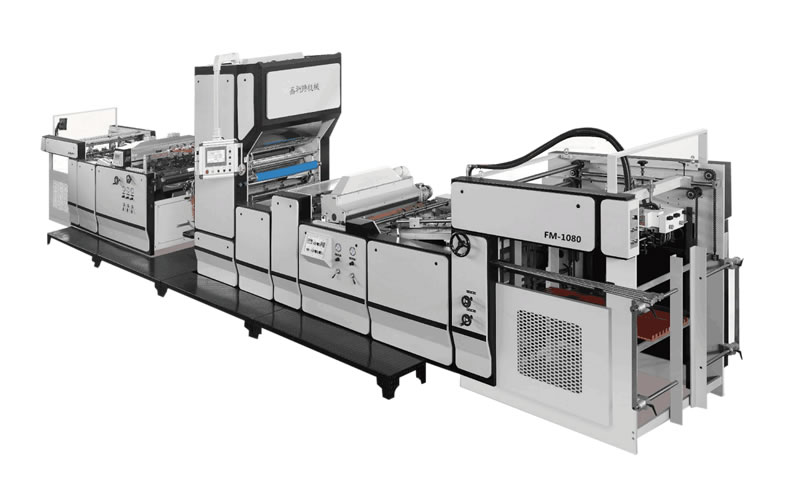

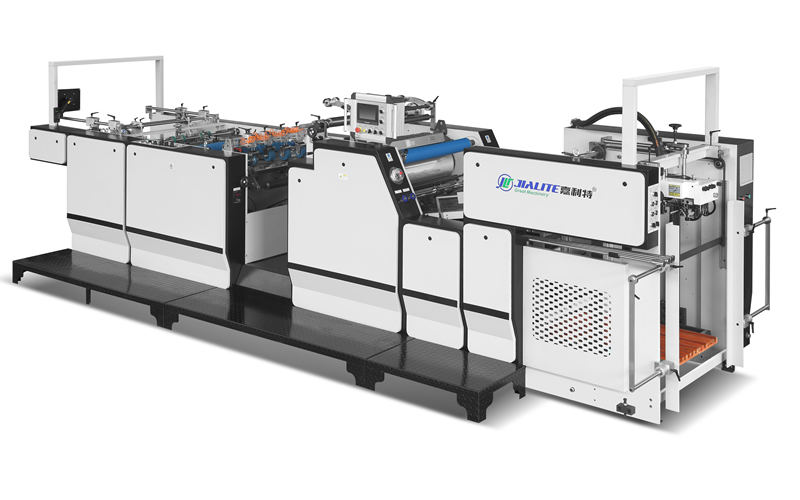

FY series pre-coat glue automatic thermal laminating machine as a professional equipment used for plastic film laminating on the surface of paper printed matter. Widely applicable for laminating in advertising poster, Picture books and magazine, display book, color paper box, calendars, and commercial cards fields, Improving the printing matter grades, and achieve the purpose of dustproof, waterproof, oil proof.

FEEDING UNIT

The automatic paper feeding part has the function of paper pre-piling and paper feeding continuously to guarantee laminating process continuous and stable, Non-stop paper sheet feeding and collecting, save time and improve productivity. Feeder for high speed printing machine which has stable paper feed and accurate and simple operation.

LAMINATOR HOST AND EAGE LANDING UNIT

The steel hot-press steel roller (Dia.380mm) adopts electromagnetic heating system, electromagnetic heating cover is installed on the top of the steel roll, Rapid heating, energy saving and environmental protection. Side guide make sure the paper on the same line, automatic overlap device. The paper edge lap device controlled by servo motor independent, that accuracy of up to ≤ ±2mm.

CUTTING UNIT

Cutting part with round (fly) knife device, easy adjustment. It can make sure effective cutting for paper more than 105g/m². Cutter with the anti-roll device, it could be appropriate to improve the curl phenomenon when the thin paper to be pull-breaking. The cutter adopts variable frequency speed control which could able to synchronize with the laminator unit part.

COLLECTOR UNIT

The automatic paper collecting part has the function of collecting paper without shutdown, the collector size is matched with the paper feeder.

1. Automatic paper feeding with servo front positioning system.

2. Main laminating machine (diameter of pressing steel roll is 380mm)

3. The Cutting unit adopt automatic pneumatic bouncing with a round knife.

4. Automatic paper collector (with non-stop paper receiving)

Option Configuration

Powder remover device, Chain knife, hot knife, UV dry (laminator more strong).

① Automatic Paper Feeding+Main Laminator Unit

lThe servo drive is matched

with the laminator unit, paper overlap precision is ±2mm.

lWith paper shortage detector

and Emergency stop device.

lWith front positioning

mechanism - servo drive.

lOil free suction air pump.

lComplete machine linkage

drive system, frequency conversion and speed regulation. Between the laminator

and the paper cutter have operation platform, Easy to clean steel roller and

rubber roller.

lWith film puncher and waste

film cutter.

lPressure roller surface is

covered with a hard special rubber.

lPressing roller hard chrome

plated steel roller dia. is 380mm, roller with electromagnetic heating system,

stable temperature.

lLaminating pressure control

with two sets of oil cylinders and automatic oil pressure system adjustment,

make sure the pressure roller and pressing roller with the balance

pressure.

lPositioning mechanism with

pull gauge;

②Automatic Pneumatic Bouncing + Collector Unit

l Round knife cutting system, Hole puncher, breaking

speed can micro adjustment.

lPLC programmable special module linkage system, can

automatically increase or decrease according to the speed of laminating.

lWith anti crimping mechanism, effectively ensuring the

flattening of thin paper.

lWith wave type collecting mechanism good for thin

paper collection.

lWith counter, it can automatically stop when the

quantity reach the setting data.

lBlowing device good for thin paper collection.

lWith four side paper patting device, paper collecting

to be tidy.